Kyzen Solutions is a consulting and services company headquartered in Houston, Texas with Operations in USA (Houston), and India (Chennai). The company was founded by ASQ certified Lean Six sigma professionals with vast experience (25+years) in oil and gas, manufacturing, technology solutions and environmental engineering.

Our expert team has improved flow, established new process and saved companies in millions of dollars. We collaborate with clients to arrive at practical and optimal solutions in expedient and cost conscious manner.. Our strength is our team expertise and our ability to combine our offshore engineering capabilities with on-site delivery at high quality levels ensuring customer Satisfaction

Why Kyzen ?

We meet client staffing augmentation needs with well matched functional and technical consultants to ensure smooth execution of projects. We are a responsive, agile partner that addresses and delivers flexible solutions to business and IT challenges. Leadership expertise in Business/Operational Excellence, Lean, Cost reduction, Process Re-engineering/process improvements/workflows, Business Intelligence/metrics, Business Process Outsourcing, Supplier development & Quality workflows Our near-shore and offshore delivery model and solutions consulting provides balance and expertise for: • Industry/ Domain knowledge • Technical Expertise • Process understanding • Cost-effective delivery

Cost effectiveness:

We always offer best value at affordable prices

Faster implementation time:

As we understand the customer requirements very well and since we plan our implementations well, we offer the least possible implementation time

Our expert team has improved flow, established new process and saved companies in millions of To provide cost effective solutions in addressing your needs in engineering, process improvements, HSE systems compliance, operations and technological challenges in achieving business excellence.

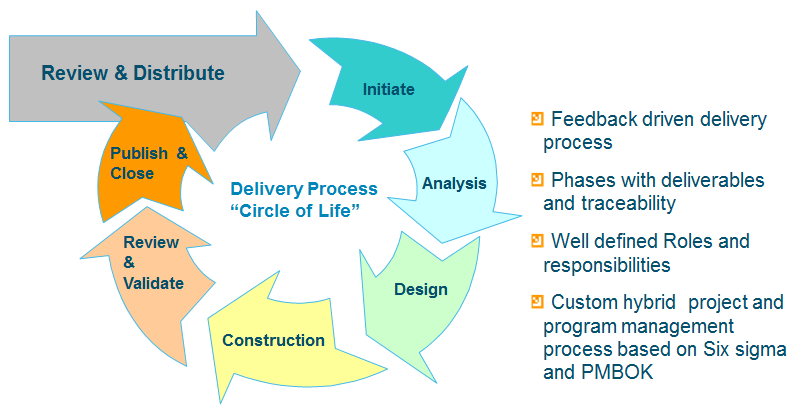

Our delivery approach provides a proven, integrated model, flexible alternatives, and a common management structure tailored to meet your cost, resource, project, and risk requirements.

Delivery Process

We help customers in the aerospace, power generation, oil & gas, energy, healthcare, retail and transportation verticals to ensure compliance to industry standards , improve processes to cut product development costs, shorten lead times, extend capacity and maximize resources.